![]() Download in PDF format [1.6 Mb]

Download in PDF format [1.6 Mb]

- Three Reasons to Cut Energy Use

- Motors are the Key

- Payback in Less than Three Years

- MotorMaster+ Calculates the Savings

Let's face it: making bowling pins isn't something you'd naturally associate with a need for electrical energy efficiency. Bowling has been around for hundreds of years, so the technology to make the pins should be pretty well optimized, right? Well, yes, but there's more to the story than that.

Let's face it: making bowling pins isn't something you'd naturally associate with a need for electrical energy efficiency. Bowling has been around for hundreds of years, so the technology to make the pins should be pretty well optimized, right? Well, yes, but there's more to the story than that.

A little background: Bowling as we know it today became popular around the turn of the 20th Century. Interest peaked in the 1960s, when there were more than 12,000 bowling centers in the country. Only about half of them are still in business today, but the sport is rebounding thanks to improved technology in equipment and scoring systems plus the introduction of snazzy entertainment options.

That's just fine with QubicaAMF, the industry leader. If only part of that name rings a bell, you're probably familiar with the U.S. half of the company, which began as American Machine and Foundry (AMF) more than 106 years ago. The company eventually became the dominant player in the industry. It continues today as a 50-50 partnership between AMF Bowling Products and Italy-based Qubica Worldwide, supplying virtually everything associated with the sport of bowling, including the lowly, but not entirely low-tech, pins.

Back to TopThree Reasons to Cut Energy Use

So, what do bowling pins have to do with energy conservation? Ron Mizzi and Rick Streeter know. They're the plant engineer and purchasing agent, respectively, for the Pins Division at QubicaAMF's plant in Lowville, New York. "Making bowling pins is actually quite energy-intensive," Mizzi explains. "We kiln-dry the wood in-house, which uses a lot of thermal energy; then we plane, rip and assemble boards into glued pre-forms called billets ( Figure 1). After the glue cures, the billets are turned into pins on special lathes ( Figure 2), a plastic base is attached, and paint, markings and an extruded plastic coating are applied. The correct temperature and humidity has to be maintained throughout all this work. That can be expensive since our plant is in northern New York State. We operate more than 230 motors, many of them driving blowers and fans on our massive air-handling equipment ― and those motors use a lot of energy!

Figure 1. A rough-turned bowling pin and the built-up billet from which it is made. Turning is only one of many energy-intensive steps in the pin's manufacture.

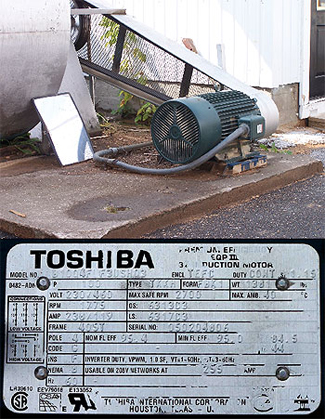

Figure 1. A rough-turned bowling pin and the built-up billet from which it is made. Turning is only one of many energy-intensive steps in the pin's manufacture. Figure 2. Pin-turning lathes at QubicaAMF (top) are now powered by NEMA Premium-rated motors (nameplate), one of many motor upgrades the company made to cut its energy costs.

Figure 2. Pin-turning lathes at QubicaAMF (top) are now powered by NEMA Premium-rated motors (nameplate), one of many motor upgrades the company made to cut its energy costs."We had to reduce our energy usage and costs," says Mizzi, "first, because those costs are a big part of our operating budget. Utility rates here in the Northeast are among the highest in the country, and ours are almost twice the U.S. average. Moving to a cheaper energy location isn't an option for us because we want to stay close to the source of hard maple, our main raw material, which is only harvested north of the 45th parallel.

"Second, like other industries, we're audited by the state to make certain we don't waste energy. We burn our wood waste in our own boiler to produce process heat, which helps a lot. We also cut our water bill 50% by recycling, and we're very careful about protecting the environment.

"Finally ― and this is something we can't control ― the price of bowling pins has basically been flat for 15 years. So we're faced with rising costs, mainly due to energy, and a static product price. We've grown our business by introducing new products like colored pins, and we even recycle worn pins to make popular trophy and birthday pins ( Top photo), but to stay strongly competitive, we want to get our energy costs down."

Back to TopMotors are the Key

When energy costs are an issue, smart facilities managers know that motors are one of the first places to look. The Department of Energy estimates that in industrial settings, motor-driven systems account for almost two-thirds of all electrical energy consumed. The Lowville plant was built in 1944; AMF bought it in 1969 and added the injection molding facility in 1976. Some of the plant's 232 motors were old and inefficient. On the other hand, buying high-efficiency replacements would require substantial capital.

In 2004, QubicaAMF's motor supplier, Terry Blodgett, (he manages the Watertown, New York branch of Kaman Industrial Systems) brought some good news. First, he showed Rick Streeter how NEMA Premium ® motors can pay for themselves in just a few years through energy savings. Then, to sweeten the pot, he told the purchasing agent about incentives being offered by the New York State Energy Research and Development Authority (NYSERDA). As Streeter remembers it, "Terry told us we qualified for incentives of up to hundreds of dollars on top-of-the-line premium-efficiency motors. NYSERDA would even show us which motors would give us the best returns on our money."

As part of the New York Energy $mart sm Program incentives, NYSERDA aims to reduce energy waste by encouraging the purchase of motors that meet or exceed NEMA Premium efficiency standards. Premium-efficiency motors use far less energy for equivalent output than old "standard" efficiency motors. They're even a few percentage points more efficient than the so-called "EPAct motors" that have been sold in the U.S.A. since 1997. 1

Subsidies under the Energy $mart program range from $25 for a 1-hp motor to $480 for a 200-hp model and represent savings of up to about 12% off distributor-discounted prices. Only motors that meet or exceed NEMA Premium efficiency standards qualify for incentives and only companies served by participating utilities are eligible to participate in the program, and then only if the company pays the utility's system benefits charge. No tax monies are involved. Numerous utilities throughout the country ― and one or two states ― offer similar plans.

Payback in Less than Three Years

With Blodgett's help, Mizzi and Streeter cherry-picked a few motors that were obvious candidates for replacement. Results were impressive, to say the least.

For example, an old, 100-hp, standard-efficiency motor powered the large blower at the plant's bag house ( Figure 3). Operating 5,000 hours per year at 80% of full load, the old 91.2%-efficient motor consumed 327,095 kWh per year, costing QubicaAMF $42,522 in energy charges annually. QubicaAMF replaced the motor with a NEMA Premium-rated Toshiba EQP III running at 95.4% efficiency. Purchasing and installing the new motor entailed a premium of $4,579 after the distributor's discount and a $325 Energy $mart incentive. Yet, because the premium-efficiency motor saved 14,464 kWh worth $1,880 annually, it paid for itself in less than 2½ years. Had the incentive not been available, the Toshiba would have taken only two additional months to pay back its purchase price. That's how important premium efficiency can be!

The best part is yet to come: That motor alone will continue to add $1,880 to the bottom line every year, and that could be a long time. NEMA Premium motors run cooler than standard or Epact models since those motors waste a lot less energy as heat, and it is well known that cool-running motors tend to last longer.

Next in line were the lathe motors ( Figure 1) and a standard-efficiency 15-hp blower motor that drove another large air-handling system ( Figure 4). This system also operates 5,000 h/y with a motor running at 80% of full power. The old motor was replaced with a NEMA Premium-efficiency Leeson Wattsaver, which saves the company 4,010 kWh and $521 per year. It paid back its $882 net installed cost in just a year and eight months. Looked at another way, that payback represents a whopping 90% return on investment!

Figure 3. A NEMA Premium-rated 100-hp Toshiba EQPIII now powers the large blower (top) at the plant's baghouse. The new motor operates with 95.4% efficiency (dataplate, bottom), saving the company $1880 annually in energy costs compared with the standard-efficiency motor it replaced. It paid for itself in only 2.43 years.

Figure 3. A NEMA Premium-rated 100-hp Toshiba EQPIII now powers the large blower (top) at the plant's baghouse. The new motor operates with 95.4% efficiency (dataplate, bottom), saving the company $1880 annually in energy costs compared with the standard-efficiency motor it replaced. It paid for itself in only 2.43 years. Figure 4. One portion of the extensive air-handling equipment at QubicaAMF's Lowville, New York pin plant. The equipment controls sawdust and collects wood waste, which is burned to produce process heat. The NEMA Premium-rated 15-hp Leeson that now powers the blower (inset) saves the company $521 annually and paid back its $882 installed cost in less than two years.

Figure 4. One portion of the extensive air-handling equipment at QubicaAMF's Lowville, New York pin plant. The equipment controls sawdust and collects wood waste, which is burned to produce process heat. The NEMA Premium-rated 15-hp Leeson that now powers the blower (inset) saves the company $521 annually and paid back its $882 installed cost in less than two years.MotorMaster+ Calculates the Savings

Blodgett brought in one of the resources he utilizes frequently, Applied Proactive Technologies (APT), the NYSERDA contractor that administers the authority's Enhanced Commercial Industrial Performance Program(ECIPP) incentives. 2 APT conducted a full motor inventory at the Lowville plant, including the motors' nameplate data, which, along with operating parameters provided by Mizzi and Streeter, was then uploaded into MotorMaster+, a motor-cost evaluation program developed by the U.S. Department of Energy. The program's built-in database contains costs and operating characteristics for hundreds of motors, making comparisons easy. The software is versatile and user-friendly for anyone with a nominal understanding of motor-related energy costs. MotorMaster+ software is available by request at AMO Tools Help Desk.

Qubica AMF's accountants insisted new motors should pay for themselves in three years or less, which the NEMA Premium motors obviously did. That's actually pretty generous: Experience shows that high-duty-cycle motors operating in a high-rate area like the Northeast usually pay back their capital investment in less than two years. 3 The higher the duty cycle and load factor, and the higher the utility rate, the faster the payback. In QubicaAMF's case, MotorMaster+ calculated a list of annual savings and projected payback periods for each motor in inventory, providing three choices of replacements having comparable operating characteristics ( Figure 5). The calculations took into account distributor discounts as well as the Energy $mart incentive.

Figure 5. A small portion of the batch motor analysis performed for QubicaAMF by Applied Proactive Technologies using MotorMaster+. The numbers in the far-left column refer to a few of the plant's 232 operating motors. The DOE software projected total annual savings of $17,850 for the motors the company chose to replace with NEMA Premium-rated models.

Figure 5. A small portion of the batch motor analysis performed for QubicaAMF by Applied Proactive Technologies using MotorMaster+. The numbers in the far-left column refer to a few of the plant's 232 operating motors. The DOE software projected total annual savings of $17,850 for the motors the company chose to replace with NEMA Premium-rated models.So far, Streeter and Mizzi have replaced 21 motors with NEMA Premium models, yielding continuing, annual savings of $17,850. They've got their sights on additional motors, which they'll upgrade over the coming years. How much can your plant save by replacing inefficient motors? To find out, MotorMaster+ software is available by request at AMO Tools Help Desk. We think you'll be pleasantly surprised by the answer.

The Principals

Ron Mizzi is plant engineer for the Pins Division of QubicaAMF, 7412 Utica Boulevard, Lowville, NY 13367-USA. He can be reached at [email protected].

Ron Mizzi is plant engineer for the Pins Division of QubicaAMF, 7412 Utica Boulevard, Lowville, NY 13367-USA. He can be reached at [email protected]. Rick Streeter is purchasing agent for QubicaAMF's Pins Division in Lowville. He can be reached at [email protected].

Rick Streeter is purchasing agent for QubicaAMF's Pins Division in Lowville. He can be reached at [email protected]. Terry Blodgett is manager of the Watertown, New York branch of Kaman Industrial Technologies, a nationwide electrical and industrial equipment distributor. Mr. Blodgett can be reached at 131 Moulton Street, Watertown, NY 13601, (315) 782-1020, and at [email protected].

Terry Blodgett is manager of the Watertown, New York branch of Kaman Industrial Technologies, a nationwide electrical and industrial equipment distributor. Mr. Blodgett can be reached at 131 Moulton Street, Watertown, NY 13601, (315) 782-1020, and at [email protected].

Footnotes

-

As used in this article, the term "premium-efficiency" refers to motors meeting NEMA Premium

® efficiencies, conforming to NEMA MG 1-2006, Tables 12-12 and 12-13.

As used in this article, the term "premium-efficiency" refers to motors meeting NEMA Premium

® efficiencies, conforming to NEMA MG 1-2006, Tables 12-12 and 12-13. -

Programs such as ECIPP are known as "Demand-Side Management" (DSM) incentives. The programs seek to reduce both energy waste and the generation of carbon dioxide from power plants. First popularized in the early 1990s and encouraged under the Energy Policy Act of 1992 (EPAct 92), DSM programs typically permit utilities to collect a system benefit charge (a user participation fee) from subscribers, the proceeds from which underwrite incentive programs such as ECIPP. A good description of these programs can be found in a report issued by the Consortium for Energy Efficiency: CEE report: U.S. Energy-Efficiency Programs, a $2.6 Billion Industry, which is available for download from the

CEE website.

Programs such as ECIPP are known as "Demand-Side Management" (DSM) incentives. The programs seek to reduce both energy waste and the generation of carbon dioxide from power plants. First popularized in the early 1990s and encouraged under the Energy Policy Act of 1992 (EPAct 92), DSM programs typically permit utilities to collect a system benefit charge (a user participation fee) from subscribers, the proceeds from which underwrite incentive programs such as ECIPP. A good description of these programs can be found in a report issued by the Consortium for Energy Efficiency: CEE report: U.S. Energy-Efficiency Programs, a $2.6 Billion Industry, which is available for download from the

CEE website.