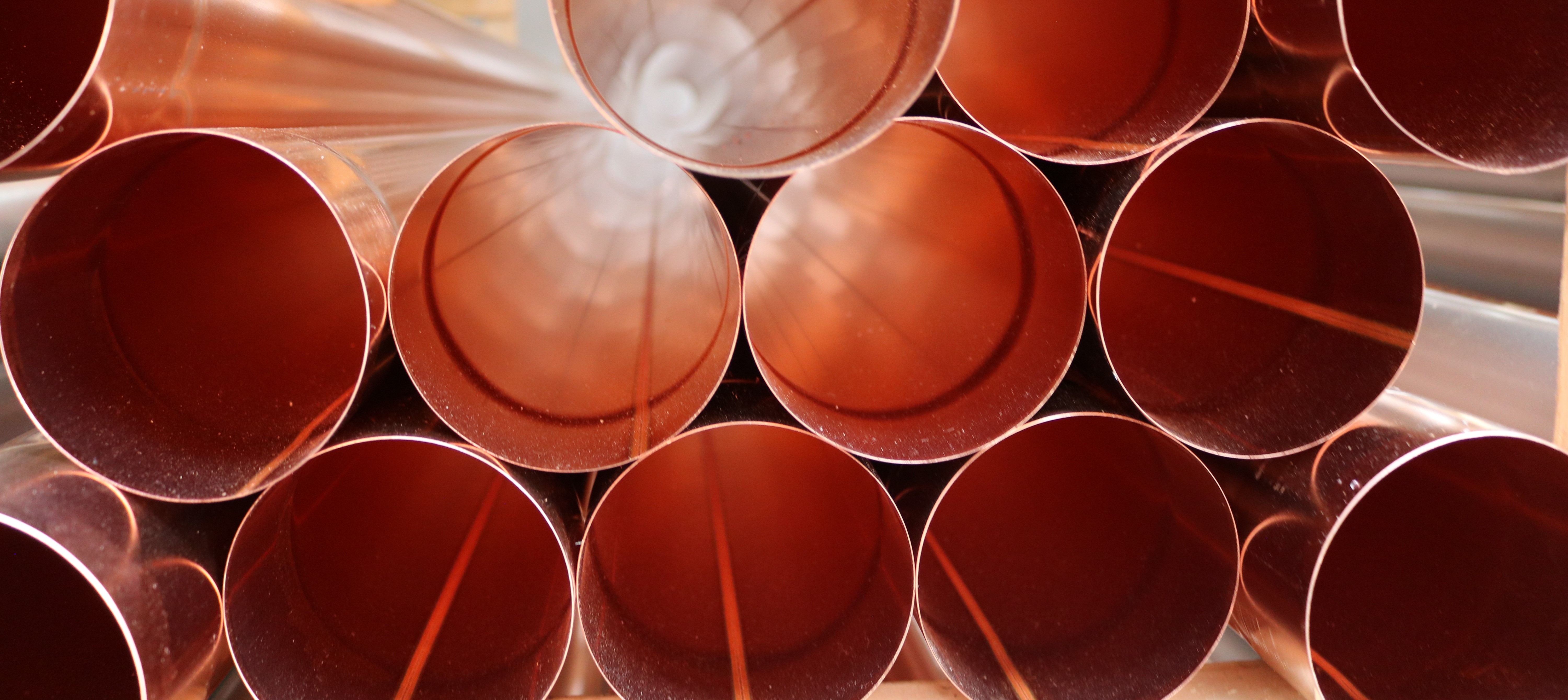

A more sustainable future relies on the use of copper. The need to build structures that are healthy for their occupants and use less electricity and water, makes copper the top material choice for architectural and interior elements, building system controls, plumbing and HVAC equipment, mechanical systems and appliances, and energy generation, storage, and electrical applications.

Why is copper critical to a green and healthy building?

Copper’s versatility is a plus for better building construction, needed for structural necessities to aesthetic adornments, including roofing, wiring, renewable energy applications, and plumbing.

Building Better: A Guide to Copper in Green and Healthy Buildings [PDF - 2.16 MB]

3rd Party Verified Heath Product Declarations (HPDs)

Copper is one of the few materials to have products with HPDs verified by a 3rd party. The verification enables a user to seek additional points under the recently revised Material Ingredients credits in LEED 4.1.

Copper Air Conditioning and Refrigeration Tube - Type ACR - per ASTM B280 [PDF - 100 KB]

Copper Medical Gas Tube per ASTM B819 [PDF - 99 KB]

Copper Natural Gas and Liquified Petroleum (LP) Gas Tube – Type GAS – per ASTM B837 [PDF - 101 KB]

Copper-Nickel Alloy Plate, Sheet, Strip, and Rolled Bar per ASTM B122 [PDF - 123 KB]

Copper Sheet and Strip for Building Construction per ASTM B370 [PDF - 96 KB]

Copper Water Tube - Type K, L, or M - per ASTM B88 [PDF - 100 KB]

Free-Cutting Brass Rod, Bar and Shapes per ASTM B16 [PDF - 106 KB]

Lead-free Brass Forging Rod, Bar and Shapes per ASTM B124 [PDF - 104 KB]

Wrought Copper and Copper Alloy Solder-Joint Pressure Fittings per ASME B16.22 [PDF - 103 KB]

Life Cycle Assessment - Copper Tube and Sheet

As an association committed to promoting the sustainable use of copper materials, CDA developed a life cycle assessment (LCA) for copper tubes and sheets produced in North America in accordance with ISO 14040/44 and ISO 21930. With a cradle-to-gate scope, this LCA can be used by manufacturers as an input to their own product-specific LCAs and Environmental Product Declarations (EPDs). Additionally, this data was incorporated into the GaBi database allowing for quick and efficient use of the results. For a list of participating manufacturers, please contact [email protected].

Life Cycle Assessment - Copper Tube and Sheet [PDF - 1.64 MB]

Toxnot Shared Materials

One of the biggest hurdles for today’s manufacturers exploring options to streamline the safety of their products is gathering product and material data efficiently from suppliers. CDA and Toxnot have improved manufacturers’ abilities to achieve full material disclosure for safer product design through their publication of over 700 shared materials, which represent all the active wrought and cast copper and copper alloy products registered in the Unified Numbering System (UNS) for alloy designations, on the Toxnot platform. Each shared material contains information on the alloy’s contents, potential health, safety, and environmental impacts, and their status with various regulatory schemes like REACH and RoHS. This puts material transparency directly at the fingertips of manufacturers using or seeking to use copper and copper alloys, supporting their ability to meet product compliance requirements and obtain sustainable certifications for their products more easily.

Toxnot Shared Materials [External website]